Eigenskip

HELLER 1089MK7 Reflow Soldering Oven

● Reflow oven lingte is 465cm (183'').

● Process Gas Opsjes: Lucht en stikstof.

● Heating sône: Up 9 / Bottom 9

● Maksimum PCB-breedte: 55,9 sm (22 inch)

● Mei it brûken fan it lêste ûntwerp fan 'e leech boppekant, is de oerflaktemperatuer fan' e masine leger, miljeubeskerming en enerzjybesparring

● Optimalisearre nije ferwaarmingsmodule, dy't stikstofferbrûk kin ferminderje mei oant 40%

● Ynnovatyf flux herstelsysteem, maklik te ferfangen en skjin te meitsjen

● Ekstreem fleksibele delgeande helling, de nije sterke kâlde loftkoelmodule kin in koelingsnivo fan mear as 3 graden per sekonde leverje

● HELLER eksklusive proprietêre software foar enerzjybehear

● Fergees yntegreare CPK-software, gegevensbehear op trije nivo's

● Kompatibel mei Yndustry 4.0

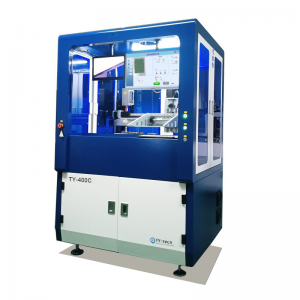

Detail Image

Spesifikaasjes

|

| ||

| 1809MK7(Loft) | 1809MK7(stikstof) | |

| Elektryske Supply |

|

|

| Power Input (3 Phase) Standert | 480 volt | 480 volt |

| Breaker Grutte | 100 amps @ 480v | 100 amps @ 480v |

| kW | 8.5 - 16 Trochrinnende | 7,5 - 16 Trochrinnende |

| Typyske Run Current | 25- 35 amps @ 480v | 25- 35 amps @ 480v |

| Opsjonele Power Inputs beskikber | 208/240/380/400/415/440/480VAC | 208/240/380/400/415/440/480VAC |

| Frekwinsje | 50/60 Hz | 50/60 Hz |

| Sekwinsjele sône ynskeakelje | S | S |

| Ofmjittings |

|

|

| Algemiene Oven Ofmjittings | 183" (465 sm) L x60"(152cm) Bx57"(144cm) H | 183" (465 sm) L x60"(152cm) Bx57"(144cm) H |

| Typysk netto gewicht | 4343lbs.(1970 kg) | 4550 lbs.(2060 kg) |

| Typysk ferstjoergewicht | 5335lbs.(2420 kg) | 5556lbs.(2520 kg) |

| Typyske Shipping Dimension | 495 x 185 x 185 sm | 495 x 185 x 185 sm |

| Kompjûter kontrôle |

|

|

| AMD of Intel basearre kompjûter | S | S |

| Flat Screen Monitor w / Mount | S | S |

| Windows bestjoeringssysteem | Windows10Ò Thús | Windows10Ò Thús |

| Auto Start Software | S | S |

| Data Logging | S | S |

| Wachtwurd beskerming | S | S |

| LAN Networking | O | O |

| Inerte sfear |

|

|

| Minimum PPM Oxygen | - | 10-25 PPM* |

| Waterless Cooling w / Flux Separation System | - | O |

| Nitrogen On / Off Valve | - | O |

| Oxygen Monitoring System | - | O |

| Nitrogen Standby System | - | O |

| Typyske stikstof konsumpsje | - | 500 - 700 SCFH ** |

| Oanfoljende funksjes | ||

| KIC Profiling Software | S | S |

| Signal Light Tower | S | S |

| Powered Hood Lift | S | S |

| Fiif (5)Termocouple profilearring | S | S |

| Redundante Alarm Sensors | O | O |

| Intelligent Exhaust System | O | O |

| KIC Profiler / ECD Profiler | O | O |

| Sintrum Board Support | O | O |

| Board Drop Sensor | O | O |

| Board Counter | O | O |

| Bar Code Reader | O | O |

| Oanpaste ferve & Decal | O | O |

| Batterij Reservekopy foar Conveyor en PC | O | O |

| GEM / SECS ynterfacing | O | O |