Fitur

HELLER 1089MK7 Reflow Soldering Oven

● Dawane oven reflow yaiku 465cm (183 inci).

● Pilihan Gas Proses: Udara lan Nitrogen.

● Zona pemanasan: Ndhuwur 9/Ngisor 9

● Jembar PCB Maksimal: 55,9cm (22")

● Nggunakake desain tutup ndhuwur kurang paling anyar, suhu lumahing mesin luwih murah, pangayoman lingkungan lan energi nyimpen

● Optimized modul panas anyar, kang bisa nyuda konsumsi nitrogen nganti 40%

● Sistem pemulihan fluks inovatif, gampang diganti lan diresiki

● slope mudhun banget fleksibel, modul cooling online kadhemen kuwat anyar bisa nyedhiyani tingkat cooling luwih saka 3 derajat per detik

● Piranti lunak manajemen energi eksklusif HELLER

● Piranti lunak CPK terpadu gratis, manajemen data telung tingkat

● Kompatibel karo Industri 4.0

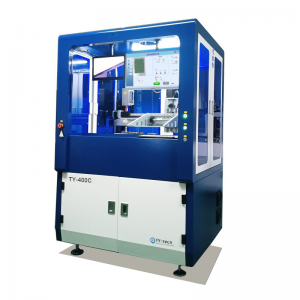

Gambar Detail

Spesifikasi

|

| ||

| 1809MK7(Udara) | 1809MK7(Nitrogen) | |

| Pasokan Listrik |

|

|

| Input Daya (3 Phase) Standar | 480 volt | 480 volt |

| Ukuran Breaker | 100 amp @ 480v | 100 amp @ 480v |

| kW | 8.5 - 16 Terus | 7.5 - 16 Terus-terusan |

| Arus Run Khas | 25- 35 amp @ 480v | 25- 35 amp @ 480v |

| Input Daya Opsional Kasedhiya | 208/240/380/400/415/440/480VAC | 208/240/380/400/415/440/480VAC |

| Frekuensi | 50/60 Hz | 50/60 Hz |

| Zona Sequential Aktifake | S | S |

| ukuran |

|

|

| Sakabèhé Oven Dimensi | 183" (465cm) L x60” (152cm) P x 57” (144cm) H | 183" (465cm) L x60” (152cm) P x 57” (144cm) H |

| Bobot Net Khas | 4343lbs.(1970 kg) | 4550 lbs.(2060 kg) |

| Bobot Pengiriman Khas | 5335lbs.(2420 kg) | 5556lbs.(2520 kg) |

| Ukuran Pengiriman Khas | 495 x 185 x 185 cm | 495 x 185 x 185 cm |

| Kontrol Komputer |

|

|

| AMD utawa Intel Based Computer | S | S |

| Monitor Layar Datar w/Mount | S | S |

| Sistem Operasi Windows | Windows10Ò Ngarep | Windows10Ò Ngarep |

| Piranti Lunak Miwiti Otomatis | S | S |

| Data Logging | S | S |

| Pangreksan Sandi | S | S |

| Jaringan LAN | O | O |

| Atmosfer Inert |

|

|

| Minimal Oksigen PPM | - | 10-25 PPM* |

| Waterless Cooling w/ Flux Separation System | - | O |

| Nitrogen On/Off Valve | - | O |

| Sistem Monitoring Oksigen | - | O |

| Sistem Nitrogen Standby | - | O |

| Konsumsi Nitrogen Khas | - | 500 - 700 SCFH ** |

| Fitur Tambahan | ||

| Piranti Lunak Profil KIC | S | S |

| Menara Lampu Sinyal | S | S |

| Powered Hood Lift | S | S |

| Lima (5) Profil Termokopel | S | S |

| Sensor Weker Keluwih | O | O |

| Sistem knalpot cerdas | O | O |

| Profiler KIC / Profiler ECD | O | O |

| Dhukungan Papan Pusat | O | O |

| Papan Drop Sensor | O | O |

| Papan Counter | O | O |

| Bar Code Reader | O | O |

| Kustom Paint & Decal | O | O |

| Baterei Serep kanggo Conveyor lan PC | O | O |

| GEM/SECS Interfacing | O | O |