Fitur

HELLER 1089MK7 Reflow Soldering Oven

● Reflow oven panjangna 465cm (183 inci).

● Pilihan Gas Prosés: Hawa jeung Nitrogén.

● Zona pemanasan: Ka luhur 9/Ka handap 9

● Lebar PCB Maksimum: 55,9cm (22")

● Ngagunakeun desain panutup luhur low panganyarna, suhu permukaan mesin leuwih handap, panyalindungan lingkungan jeung hemat energi

● Dioptimalkeun modul pemanasan anyar, nu bisa ngurangan konsumsi nitrogén ku nepi ka 40%

● Sistim recovery fluks inovatif, gampang pikeun ngaganti tur bersih

● lamping turun pisan fléksibel, modul cooling hawa tiis kuat anyar bisa nyadiakeun laju cooling leuwih ti 3 derajat per detik

● HELLER ekslusif software manajemén énergi proprietary

● software CPK terpadu bébas, manajemén data tilu-tingkat

● Cocog jeung Industri 4.0

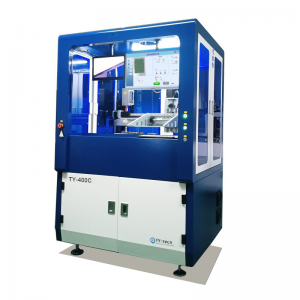

Gambar Rincian

spésifikasi

|

| ||

| 1809MK7(hawa) | 1809MK7(Nitrogén) | |

| Pasokan listrik |

|

|

| Input kakuatan (3 Phase) Standar | 480 volt | 480 volt |

| Ukuran Breaker | 100 amps @ 480v | 100 amps @ 480v |

| kW | 8.5 - 16 Satuluyna | 7.5 - 16 Terus-terusan |

| Biasa Run Ayeuna | 25- 35 amps @ 480v | 25- 35 amps @ 480v |

| Input Daya Pilihan Sadia | 208/240/380/400/415/440/480VAC | 208/240/380/400/415/440/480VAC |

| Frékuénsi | 50/60 Hz | 50/60 Hz |

| Zona Sequential Hurungkeun | S | S |

| Diménsi |

|

|

| Gemblengna Oven Dimensi | 183" (465cm) L x60” (152 cm) P x 57” (144cm) H | 183" (465cm) L x60” (152 cm) P x 57” (144cm) H |

| Beurat Net has | 4343lbs.(1970 kg) | 4550 pon(2060 kg) |

| beurat Pangiriman has | 5335lbs.(2420 kg) | 5556lbs.(2520 kg) |

| Diménsi Pangiriman has | 495 x 185 x 185 cm | 495 x 185 x 185 cm |

| Kontrol Komputer |

|

|

| AMD atanapi Intel Based Computer | S | S |

| Monitor layar datar w / Gunung | S | S |

| Sistem Operasi Windows | Windows10Ò Imah | Windows10Ò Imah |

| Otomatis Mimitian Software | S | S |

| Data Logging | S | S |

| Protéksi Sandi | S | S |

| Jaringan LAN | O | O |

| Atmosfir Inert |

|

|

| Oksigén PPM minimum | - | 10-25 PPM* |

| Waterless cooling w / Sistim separation fluks | - | O |

| Nitrogén On / Pareum klep | - | O |

| Sistim pangimeutan oksigén | - | O |

| Sistem Nitrogén Sayaga | - | O |

| Konsumsi Nitrogén has | - | 500 - 700 SCFH ** |

| Fitur tambahan | ||

| KIC Propil Software | S | S |

| Sinyal Lampu Tower | S | S |

| Powered Hood Angkat | S | S |

| Lima (5) Profil Termokopel | S | S |

| Sénsor Alarm kaleuleuwihan | O | O |

| Sistem knalpot calakan | O | O |

| KIC Profiler / ECD Profiler | O | O |

| Rojongan Board Center | O | O |

| Sénsor serelek dewan | O | O |

| Kontra dewan | O | O |

| Bar Code Reader | O | O |

| Custom cet & Decal | O | O |

| Cadangan Batré pikeun Conveyor sareng PC | O | O |

| GEM / SECS Interfacing | O | O |