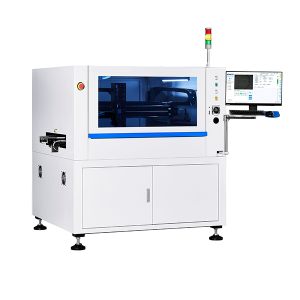

Feature

Super-fast, exceptionally precise, and a real space-saver – the numbers speak for themselves: Core cycle times from 5 to 6.5 seconds, wet-printing accuracy of ±17.0 microns @ 2 Cpk, and a footprint from 1.3 to 1.95 square meters. Maximum flexibility thanks to two versions: DEK TQ for boards up to 400 mm x 400 mm and DEK TQ L for boards up to 600 mm x 510 mm.

The machine achieves its exceptional speed in part through its three-stage transport and its unique NuMotion controllers with fiber-optic wiring. Newly developed drives, off-belt printing and innovative clamping systems ensure a new level of accuracy and an extremely stable printing process – certified by ASMPT because the precision of each machine is measured and documented prior to delivery.

The printer platform fits seamlessly into the Open Automation concept and delivers with IPC-HERMES-9852 and IPC-CFX board-related M2M and M2H communication along the line and integrates seamlessly with MES, ERP and AIV fleet management systems. In addition, a wide range of options enables even more advanced degrees of paste printing automation in the integrated smart factory.

Detail Image

Newly developed, fexible high-speed stencil cleaning system

Innovative printhead

Smart Pin Support

Specifications