Isici

●Isistimu ye-spray ye-high-pressure isetshenziselwa ngokukhethekile uketshezi lokuhlanza olusekelwe emanzini ukuhlanza isikrini, ipuleti elingaphrintiwe kahle, i-scraper yomshini wokunyathelisa nezinye izinqubo.

● Ithangi eliwuketshezi eliphindwe kabili, elifakwe isistimu yokushisisa, ukuze lihlangabezane nezidingo zokuhlanza, ukuwasha nokomisa umoya oshisayo.

●Ukugeleza kwenqubo: ukuhlanza - ukuhlukaniswa kwamakhemikhali - ukuhlanza okuqinile (iluphu evuliwe/evaliwe) - ukuhlanza kahle (iluphu evuliwe/evaliwe) - ukomisa.

● Ukulungiswa kwesofthiwe yokusebenza kwesikrini esithintwayo esithuthuke ngokuphelele, amafayela ohlelo ayagcinwa, futhi ukusetshenziswa kulula kakhulu.

●Umsebenzi wokubala wesistimu, ongaqongelela ngokuzenzakalelayo inani lama-stencil okuhlanza kanye nenani lezikhathi zokuhlunga ezizungezayo.

●Ingcindezi yoketshezi nephampu ingaboniswa ngegeji yokucindezela kwephaneli, futhi isimo sokusebenza kwesisetshenziswa singabuyiselwa ngesikhathi.

●Ingcindezi yesifutho igadwa inzwa yokucindezela, futhi i-alamu izonikezwa uma ingcindezi idlula uhla lokucindezela olumisiwe.

●Uketshezi lubuya ngqo ukuze lunciphise ukusetshenziswa koketshezi

●Umzimba wensimbi engagqwali usuwonke uqinile futhi uqinile, amelana ne-asidi, i-alkali nolunye uketshezi lokuhlanza.i

●I-high-pressure blower + ukomisa umoya oshisayo, umphumela wokomisa ushesha kakhulu futhi uphelele.

● Izindleko eziphansi zokusebenza, uketshezi oluwu-50-200ml kuphela oludingekayo ekuhlanzeni ngakunye, futhi umoya ocindezelwe usetshenziselwa ukubuyisela uketshezi olusele epayipini kanye nokupompa ngemva kokuhlanza, okunganciphisa ukusetshenziswa koketshezi ngo-50%.

Umsebenzi:

1. Indlela yokuhlanza imishini: umjovo we-fluid olinganayo wesokunxele nakwesokudla weselula ophindwe kabili emaceleni, umshini usebenzisa imojuli ye-axis ebonakalayo, isikulufu sebhola esinembayo, esishayelwa ukunyathela injini ukwenza amandla abuyele kwesokunxele nakwesokudla, ukuze kuqinisekiswe ukuthi kunembile. setha kabusha ngaso sonke isikhathi nempilo ende , kulula ukuyigcina noma ukuyishintsha, sebenzisa ibha yesifutho ephindaphinda kwesokunxele nakwesokudla ukufutha, ungakhetha indawo yendawo ukuze uzuze ukufutha okuhlosiwe, futhi ukushuba kwe-mesh yensimbi ngeke kuthinteke ngemva kokuhlanza.

2. Ukungcola kwe-solder paste kuhlukaniswa ngendlela ehlelekile, futhi ukusetshenziswa kwe-fiber adsorption kanye nemiphumela yokuhlunga kwenza ukugcinwa kube lula.

3. Ukubona ngeso lengqondo, yonke inqubo yokuhlanza, ukusebenza kwesikrini sokuthinta kulula kakhulu, umsebenzi wenkumbulo yohlelo.

4. Umshini wakhiwe uhlelo lokuhlanza, uhlelo lokusika, uhlelo lokuhlanza, uhlelo lokumisa kanye nesistimu yokuhlunga.Umshini usebenzisa ugesi negesi njengemithombo yamandla, ubeka ngesandla i-stencil ekamelweni lokuhlanza, ngemva kokusetha ukuhlanza, ukuhlanza, ukomisa kanye neminye imingcele ehlobene esikrinini sokuthinta, cindezela inkinobho yokuqala, i-stencil izohlanzwa ngokuzenzakalelayo, ihlanzwe futhi omisiwe .Lapho inqubo yokuhlanza esethiwe isiphelile, izoyeka ngokuzenzakalelayo ukusebenza futhi isethwe kabusha ukuze ibone inqubo yokusebenza elandelayo.Umsebenzi wesofthiwe womshini unamandla kakhulu, ongagcina ulwazi oluthile lokuhlanza isikrini (isikhathi, imvamisa, isikhathi sokusika, imvamisa, isikhathi sokuhlanza, imvamisa, isikhathi sokushisa sokumisa, imvamisa, njll.) yesikrini sokuhlanza.Umshini ulungele kakhulu ukuthi opharetha ahlanze iStencil, umlingani wokuqala ukuze athuthukise ukusebenza kahle kokukhiqiza kanye nekhwalithi.Iwuhlobo olusha lwemishini yokuhlanza ezenzakalelayo esebenza kahle kakhulu.Okokusebenza kusebenzisa uketshezi olusekelwe emanzini noma amanzi e-DI njenge-ejenti yokuhlanza, ngaphandle kwengozi yokuphepha futhi akukho monakalo kubasebenzi.

5. Ukomiswa komoya oshisayo: Isiphephetha-moya esinomfutho ophezulu singena ngommese womoya ngebhokisi lokushisisa ukuze some izingxenye ezihlanziwe ngokushesha.

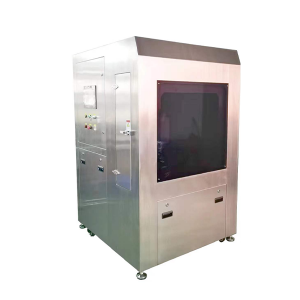

Imininingwane yesithombe

Imininingwane

| Imodeli | I-TY-S750 |

| Ubukhulu bomshini | 1220mm(L)*1120mm(W)*1850mm(H) |

| Isisindo Somshini | 580KG |

| I-stencilSize | Ubukhulu750*750*40mm |

| CukuncikaQubuthi | 1pc |

| SkhulekaPqinisa | 2-3KG (inani eliphelele lokucindezela) |

| Umthamo omkhulu wethangi eliwuketshezi | 50L*2PCS |

| Ukusetshenziswa Okufanelekile Kwe-Liquid | 40L*2PCS |

| Ivolumu yesisombululo sokusebenza esincane | 20L*2PCS |

| Namaphampu | 3ama-pcs(iphampu yokuncibilikisa engu-1, iphampu yokuwasha engu-1, iphampu yokukhipha amanzi engu-1) |

| Ukulawula/Isistimu Yokusebenza | I-Mitsubishi PLC + China Taiwan Weilun touch screen |

| CukuncikaSuhlelo | Iphampu kagesi ezimele yokucindezela okuphezulu ukuze kukhishwe isincibilikizi + kwesokunxele nakwesokudla ezihambayo ezimbili ze-isobaric nozzle nozzle nozzle high-pressure spray cleaning (Iphampu ezimele ingagwema ngempumelelo umzila we-liquid futhi inciphise imvamisa yokusebenza kwephampu ukuze inwebe imvamisa yokusetshenziswa) |

| Buyisela uhlelo | Setha isikhathi se-reflux sibe amasekhondi angu-40-60 (vumela ngokugcwele i-ejenti yokuhlanza ibuyele ethangini le-solvent ukuze wonge umthamo) |

| Rinse system | Iphampu kagesi ezimele yokucindezela okuphezulu ukuze kukhishwe amanzi okugeza + kwesokunxele nakwesokudla ezihambayo kabili emaceleni isobaric nozzle nozzle nozzle high-pressure yokuhlanza isifutho (Iphampu ezimele ingagwema ngempumelelo umzila we-liquid futhi inciphise imvamisa yokusebenza kwephampu ukuze inwebe imvamisa yokusetshenziswa) |

| Duhlelo lokukhala | Ukushisisa kwebhokisi lokushisisa + i-blower hot backflow + ishear yomoya ehamba kwesokunxele nakwesokudla |

| Fisistimu yokuhlunga | Ukuhlunga okuphakeme Ukuhlunga Kwezinga 1: Hlunga ukungcola namalebula I-2-stage filtration: isihlungi se-solder paste kanye nezinhlayiya ze-rosin Ukuhlunga okunezigaba ezi-3: izinhlayiya eziyi-1μm ezifana ne-solder paste, i-rosin, iglue ebomvu nezinto ezingcolisayo |

| UkuhlanzaPi-rinciple | Ukuhlanza okunomfutho ophezulu wesifutho + ukuhlanza |

| CukuncikaMindlela | Iphampu ye-diaphragm kagesi ikhipha i-ejenti yokuhlanza ngemva kokuhlunga, bese ifafaza ikhanda lesifutho kukholamu yamanzi emise okwefeni kubha yesifutho ye-isobaric engakwesokunxele kwesokudla eshukunyiswa kabili emaceleni kwesokudla ukuze kuhlanzwe inetha lensimbi nesikrabhu, futhi kususe unamathisele odongeni, ingcina ebomvu. , uyinki, inhlaka nokunye ukungcola Sula, bese uhlanza ngendlela efanayo |

| Izinto zokusebenza | Ifakwe ama-casters akhethekile angashintshi |

| Impahla yesisetshenziswa | 304 insimbi engagqwali (ubukhulu 1.5mm) |

| Impahla yepayipi yezisetshenziswa | Impahla ye-PPH (Impilo ende, ukumelana nezinga lokushisa eliphezulu, i-asidi eqinile kanye nokumelana ne-alkali, akukho ukukala, ukushintshwa kalula, njll.) |

| Uketshezi lokuhlanza olusebenzayo | ukuhlanza amanzi |

| Ukulahleka komjikelezo owodwa/ishidi | <200ml Kuya ngosayizi, ubuningi, isikhathi sokuhlanza, nezinga lokushisa lokushisa lomkhiqizo wokuhlanza |

| Iamandla we-nput | I-AC380V 50HZ 50A |

| Tamandla otal | 25KW |

| Ifaka umfutho womoya | 0.4-0.6MPa |

| Aivolumu yokugeleza | 200 L/min @ Ukuhlanza (kudliwe ngesikhathi sokuhlanza) 600L/Min @ Drying (ukomisa ukusetshenziswa komoya) |

| Izidingo ze-Exhaust Velocity | 7.5m³/min, vele ufake ipayipi le-exhaust elingu-Φ125 |

| Pipeline | Amaphampu amathathu namapayipi amathathu (Iphampu ezimele ingagwema ngempumelelo umzila we-liquid futhi inciphise imvamisa yokusebenza kwephampu ukuze inwebe imvamisa yokusetshenziswa) |

| Dindlela yokukhala | Ummese womoya ukusika amanzi + ukomisa umoya oshisayo (Thuthukisa umphumela wokumisa futhi unciphise isikhathi sokumisa) |

| Isimiso sokumisa | Ukushisisa kweshubhu lokushisisa, ukugeleza komoya oshisayo emuva, ukusika komoya ohlangothini lwesobunxele nakwesokudla. |

| Dizinga lokushisa elikhalayo | izinga lokushisa ekamelweni -60 ° (Ngemva kokuhlolwa okuphindaphindiwe, ukweqa okungu-60° kuzolimaza iglue yozimele wesikrini, futhi umkhawulo ongaphezulu wohlelo ngu-60° ukugwema ukulimala kohlaka lwesikrini olubangelwa ukusebenza okungalungile) |

| Inombolo yemibhobho | 22ama-pcs |

| Inani lamathangi okuhlanza | 1pc |

| Inani lamathangi okugeza | 1pc |

| Indlela yokuvala yokuhlanza ithangi | Isendlalelo sokuqala: isivalo somnyango wensimbi Isendlalelo sesibili: Sivalwe ngendandatho evimbela ukugqwala, futhi i-valve yokuphepha engenisiwe ivaliwe ukuze kuvikelwe ngempumelelo ukuphepha komsebenzisi kanye nomkhiqizo. |

| Cikhono lokuncika | I-solder paste, iglue ebomvu, noyinki kungahlanzwa ngokuphelele |

| Geza + Isikhathi Somile | Ukuhlanzwa kwe-solvent: imizuzu engu-2-5 (ngokwereferensi kuphela) Hlanza: 1-3 amaminithi (ngokwereferensi kuphela) Ukomisa: imizuzu emi-2-5 (ngokwereferensi kuphela) 1-999S isikhathi sokuhlanza nokomisa singasethwa ngokwehlukana |

| Ukuhlanza uketshezi esikhundleni indlela | Ifakwe ipayipi elikhethekile lokukhipha okuzenzakalelayo |

| Indlela yokwelapha isixazululo sokuhlanza | Ifakwe ipayipi elikhethekile lokukhipha okuzenzakalelayo |

| Viewport | Yebo (igumbi lokuhlanza lifakwe ukukhanyisa kwe-LED ukuze kubonwe kalula umphumela wokuhlanza) |

| Oiphaneli ye-peration | Isikrini sokuthinta, izinkinobho, isitobhi esiphuthumayo, ukhiye wokuqala, ukhiye wokusetha kabusha |

| Ingabe isetshenziswa ekuhlanzeni i-COB stencil | YEBO |

| Izinto ezisetshenziswayo | I-ejenti yokuhlanza esekelwe emanzini, isici sokuhlunga |

| Izinto zokulungisa, imvamisa kanye nesikhathi esiningi | 1. Ukushintshwa kwesici sesihlungi: Inyanga engu-1 (ukushintsha kuthatha imizuzu emi-5) 2. Ukushintsha i-solvent: izinyanga ezi-3 (ukushintsha kuthatha imizuzu engama-30) 3. Ukuhlanza ikhanda lokufafaza: Izinyanga eziyisi-6 (ukuhlanza kuthatha imizuzu eyi-10) Lokhu okungenhla kungokwereferensi kuphela, futhi kungashintshwa ngokukhetha ngokuya ngemvamisa yokuhlanza yomkhiqizo. |