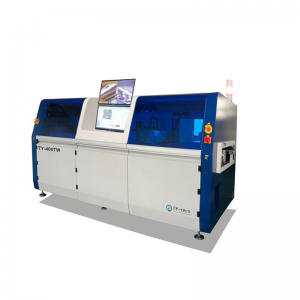

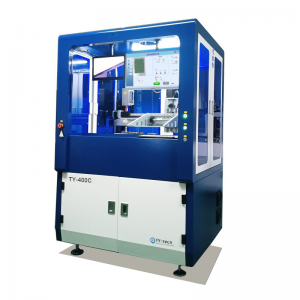

Feature

Selective wave soldering, also known as selective soldering, applies equipment in the field of PCB plug-in through-hole welding. Due to different welding advantages, through-hole welding has gradually become a popular trend in the field of PCB through-hole welding in recent years. The scope of application is not limited to: military electronics , aerospace ship electronics, automotive electronics, digital cameras, printers and other multi-layer PCB through-hole welding with high welding requirements and complex processes.

Advantageous:

a All in one machine, in same XYZ motion table combine selective fluxing and soldering, compact & full function.

b PCB board movement, fluxer nozzle and solder pot fixed.

c High quality soldering.

d Can used beside production line, flexible for production line forming.

e Full PC control. All parameters can set in PC and saved to PCB menu, like moving path, solder temperature, flux type, solder type ,n2 temperature etc, best trace-ability and easy to get repeat soldering quality.

Detail Image

Specifications

| Model | TYO-300B |

| General | |

| Dimension | L1100mm * W790mm * H1500mm (not including base) |

| General power | 3kw |

| Consumption power | 1kw |

| Power supply | single phase 220V 50HZ |

| Net weight | 280KG |

| Reuiqred air source | 3-5 Bars |

| Required air flow | 8-12L/min |

| Required N2 pressure | 3-4 Bars |

| Required N2 flow | >2 cubic meters/hour |

| Required N2 purity | 》99.998% |

| Carrier | can be used as needed |

| Max solder area | L300 * W250MM (size can be customized) |

| PCB thickness | 0.2mm-----6mm |

| PCB edge | >3mm |

| Controlling | Industrial PC |

| Loading board | Manual |

| Unloading board | Manual |

| Operating height | 700+/-30mm |

| Conveyor up clearance | no limited |

| Conveyor bottom clearance | 30MM |

| Motion axis | X, Y, Z |

| Motion control | Servo + stepper |

| Position accuracy | + / - 0.1 mm |

| Chassis | Steel structure welding |

| Flux management | |

| Flux nozzle | jet valve |

| Flux tank capacity | 1L |

| Flux tank | flux box |

| Solder pot | |

| Standard pot number | 1 |

| Solder pot capacity | 15 kgs /furnace |

| Solder temperature range | PID |

| Melting time | 30--40 Minutes |

| Max solder temperature | 350 C |

| Solder heater | 1.2kw |

| Solder nozzle | |

| Nozzle dim | custom shape |

| Material | alloy steel |

| Standard equipped nozzle | Standard configuration: 5 pieces/furnace |

| N2 management | |

| N2 heater | standard |

| N2 temp range | 0 - 350 C |

| N2 consumption | 1---2m3/h/nozzle |