Feature

It adopts turntable type station welding, which occupies a small area and has high efficiency. The equipment adopts selective wave soldering process, and the welding quality is high. Using 8 stations to work at the same time, it has high efficiency and productivity and saves labor. The equipment uses single-point welding and consumes very low energy. It has strong applicability and can realize manual and automated line docking at the same time. It can take the programming path and can cope with various products at the same time. Depending on the product, you can choose to use nitrogen or not, and you can achieve good welding results. Foolproof operation, more convenient to use. The welding consistency is good and the quality risk is reduced.

Advantageous:

a All in one machine, in same XYZ motion table combine selective fluxing and soldering, compact & full function.

b High quality soldering.

c Can used beside production line, flexible for production line forming.

d Full PC control. All parameters can set in PC and saved to PCB menu, like moving path, solder temperature, flux type, solder type ,n2 temperature etc, best trace-ability and easy to get repeat soldering quality.

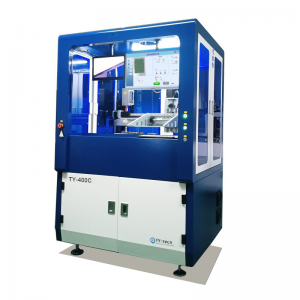

Detail Image

Specifications

| Model | TY-400C |

| General | |

| Dimension | L1000mm * W1133mm * H1810mm |

| General power | 3kw |

| Consumption power | 1kw |

| Power supply | Single phase 220V 50HZ |

| Net weight | 380KG |

| Reuiqred air source | 3-5 Bars |

| Required air flow | 8-12L/min |

| Required N2 pressure | 3-4 Bars |

| Required N2 flow | >2 cubic meters/hour |

| N2 purity | 》99.998% |

| Pallet | Can be used as needed |

| Max solder area | L320 * W400MM (Can be customized) |

| PCB thickness | 0.2mm-----6mm |

| PCB edge | >3mm |

| Controlling | Industrial PC |

| Loading board | Manual |

| Unloading board | Manual |

| Operating height | 900+/-30mm |

| Conveyor up clearance | No limited |

| Conveyor bottom clearance | 30MM |

| Motion axis | X, Y, Z |

| Motion control | stepper |

| Position accuracy | + / - 0.1 mm |

| Chassis | Steel structure welding |

| Flux management | |

| Flux nozzle | Injection valve |

| Flux tank capacity | 1L |

| Flux tank | pressure tank |

| Solder pot | |

| Standard pot number | 1 |

| Solder pot capacity | 10~15 kgs /furnace |

| Temperature range | PID |

| Melting time | 30--40 Minutes |

| Max temperature | 350 C |

| Solder heater | 1.2kw |

| Soldering nozzle | |

| Nozzle dim | Customizable shapes |

| Nozzle material | alloy steel |

| Equipped nozzle | Standard configuration: 5 pieces/furnace |

| N2 management | |

| N2 heater | Standard |

| N2 temp range | 0 - 350 C |

| N2 consumption | 1---2m3/hour/tin nozzle |