Feature

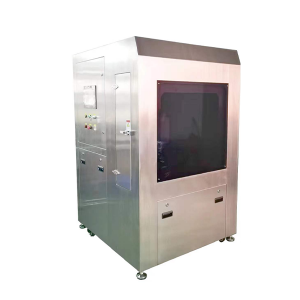

For the cleaning of SMT steel mesh, copper mesh, wire mesh, microporous mesh and wafer disk in the electronics industry: The pneumatic cleanign equipment completely uses compressed air as energy, does not use electricity, does not have any fire hazards, and adopts human nature Modern design, one-button operation, easy to complete the cleaning and drying work; it is a high-performance pneumatic fully automatic cleaning equipment that uses air pressure to fully automatic operation from cleaning to drying process, and the cleaning liquid cycle consumption is low.

Feature:

1. All stainless steel body: beautiful, wear-resistant, corrosion-resistant, in line with environmental requirements and standards;

2. Fully pneumatic operation, no electricity, no safety hazards such as fire;

3. Side wall air intake and drying design;

4. Humanized design: one-button operation and automatic filling and discharging function, the operation is very simple;

5. Replaceable modular controller and quick-plug design, easy maintenance;

6. Two-stage filtration system, low exhaust outlet and S-shaped exhaust pipe design: solvent recycling, low liquid consumption;

7. High-density isobaric double-sided rotating cleaning nozzles, strong cleaning power, without damaging the tension of the steel mesh.

8. Systematic integration of global high-quality control devices to ensure high quality, stable performance and long service life;

Cleaning objects: steel mesh, copper mesh, mesh, micromesh and crystal disc, printing scraper, misprint plate.

Maintenance and maintenance:

1. Automatic adding and draining.

2. Controller maintenance: replaceable modular control and quick-plug design; Maintenance, maintenance is simple and convenient.

Detail Image

Specifications

| Model | TY-PS750 |

| Machine Dimension | 1000mm(L) *700mm(W) *1730mm(H) |

| Stencil Size | Max 750*750*40mm |

| Cleaning Quantity | 1 |

| Spray Pressure | 1.5-2KG (total pressure value) |

| Maximum Volume of Liquid Tank | 40L |

| Optimal Liquid Usage | 30L |

| Minimum Working Solution Volume | 15L |

| Number of Pumps | 1pc |

| Control/Operate System | Long-time timer (German brand Festool) |

| Cleaning System | Independent pneumatic diaphragm pump extracts solvent + 360°rotary double-sided isobaric jet roll high-pressure jet |

| Drying System | 360°rotary double-sided isobaric drying |

| Filtering System | Tertiary filtration

Level 1 Filtration: Filter impurities and labels 2-stage filtration: filter solder paste and rosin particles 3-stage filtration: 5μm particles such as solder paste, rosin, red glue and pollutants |

| Cleaning Principle | Pneumatic diaphragm pump pumps cleaning agent through gas pressurization to spray and clean |

| Cleaning Method | The pneumatic diaphragm pump filters the cleaning agent and extracts it. The 360° rotating double-sided isobaric jet coil high-pressure sprays the fan-shaped water column to spray and clean the steel mesh and scraper, and remove solder paste, red glue, ink, resin and other dirt. |

| Machine Weight | 210KG |

| Equipment Fixtures | Equipped with special fixed casters |

| Equipment Material | 304 stainless steel material (thickness 1.5mm) |

| Applicable Cleaning Fluid | Washboard water, industrial alcohol, water-based cleaning agent |

| Single Cycle Loss/Sheet | Alcohol about 120ml, water-based about 50ml

Depending on the size, quantity, cleaning time, and heating temperature of the cleaning product |

| Input Power | no electricity |

| Input Air Pressure | 0.4-0.6MPa |

| Air Flow Volume | 400 L/min @ Cleaning (consumed during cleaning)

600L/Min @ Drying (air drying consumption) |

| Exhaust Velocity Requirements | 7.5m³/min, just install Φ125 exhaust pipe |

| Pipeline | single pump single pipe |

| Drying Method | Blow dry at room temperature |

| Drying Principle | compressed air drying |

| Drying Temperature | room temperature |

| Number of Nozzles | 28pcs |

| Number of Cleaning Tanks | 1pc |

| Closing Method of Cleaning Tank | The first layer: steel door seal

The second layer: It is sealed with an anti-corrosion sealing ring, and the imported safety valve is closed to effectively protect the safety of the operator and the product. |

| Cleaning Ability | Solder paste, red glue, and ink can be completely cleaned |

| Wash + Dry Time | Solvent cleaning: 2-5 minutes (for reference only)

Air-drying: 3-5 minutes (for reference only) Air-drying with water-based cleaning agents does not work well 1-999S cleaning and drying time can be set separately |

| Cleaning Fluid Replacement Method | Equipped with special pipeline for automatic extraction |

| Cleaning Solution Treatment Method | Equipped with special pipeline for automatic extraction |

| Viewport | NO |

| Operation Panel | Timer, push button, emergency stop, start key, pressure gauge |

| Is it used in COB stencil cleaning | YES |

| Consumables | cleaning agent, filter element |

| Maintenance items, frequency and time-consuming | 1. Filter element replacement: 1 month (replacement takes 5 minutes)

2. Replacement of solvent: 3 months (replacement takes 30 minutes) 3. Sprinkler head cleaning: 6 months (cleaning takes 10 minutes) The above is for reference only, and can be selectively replaced according to the cleaning frequency of the product. |