Feature

1.One-button operation, the entire cleaning process is completed automatically, and the rinse solution is automatically added and drained without manual intervention. The equipment has low energy consumption, low operating noise, no pollution, energy saving and environmental protection, and the overall stainless steel structure occupies a small area.

2.The functions of cleaning, rinsing, wind cutting and drying are integrated. The quantity of liquid to be drained, the times of cleaning and rinsing can be set through the man-machine interface.

3.The equipment has a cleaning and rinsing real-time circulation filtration system, which uses a double pump and double liquid circuit design, and the spray system is in a closed chamber during cleaning. The utilization efficiency of the liquid is improved, and the use cost is reduced.

4.After cleaning, the surface of the jig is dry and has a high degree of cleanliness. It can be directly used in subsequent processes, and the effect of manual cleaning is greatly improved.

5.720-degree rotating omni-directional spraying, no dead angle for cleaning + drying.

6.The cleaning batch is large, which can save a lot of labor.

7.The nozzle pressure can be monitored during the cleaning process of the machine to ensure the cleaning effect. The inner side of the cleaning chamber is treated with 0.1mm thick nano-surface treatment, which avoids water droplets remaining in the box and greatly reduces the loss of liquid.

8.Anti-slip gas spring, safe and reliable, double sensors are installed on both sides of the upper cover, and double insurance safety devices are implemented.

9.The closed structure foam can be returned to the water tank, and the PP filter element is convenient for maintenance.

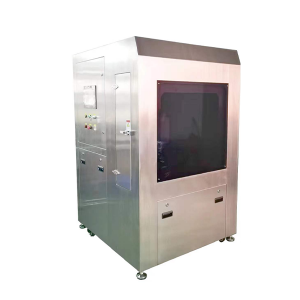

Detail Image

Specifications

| Model | TY-C800 |

| Machine Dimension | 1880(L)*1450(W)*1500(H)mm |

| Machine Weight | Appr 650kg |

| Cleaning Basket Size | 1000mm |

| Spray Pressure | 4.5-6KG (total pressure value) |

| Product Size | L800*W480mm |

| Wash Quantity (mm) | 200x480 44

300x480 24 400x480 16 |

| Maximum Volume of Liquid Tank | 50L*2PCS |

| Optimal Liquid Usage | 40L*2PCS |

| Minimum Working Solution Volume | 20L*2PCS |

| Number of Pumps | 3 (1 solvent pump, 1 rinse pump, 1 drain pump) |

| Operation/Operation System | Mitsubishi PLC + China Taiwan Weilun touch screen |

| Cleaning System | Independent electric high-pressure pump extracts solvent + 720-degree rotation for all-round high-pressure spraying |

| Return system | Set the reflow time to 40-60 seconds (features are as follows)

Fully let the cleaning agent return to the solvent tank to save the potion |

| Rinse System | Independent electric high-pressure pump pumps rinsing water + 720-degree rotation for all-round high-pressure spraying |

| Drying System | High pressure blower + heating pipe box + temperature control module + 720-degree rotating all-round wind cutting + hot air drying |

| Filtering System | 3 levels of filtration:

Level 1 Filtration: Filter impurities and labels 2-stage filtration: filter tin slag, rosin, flux and other particles 3-stage filtration: 5μm rosin, flux and other particles |

| Cleaning Principle | High pressure spray cleaning + rinsing |

| Cleaning Method | The electric diaphragm pump extracts the cleaning agent after filtering,

Fix the spray bar on the top, bottom and side to form a fan-shaped water column to perform high-pressure spray cleaning on the jig or condenser in the rotating cleaning basket to remove rosin, flux and other dirt, and then rinse in the same way |

| Equipment Fixtures | Equipped with special fixed casters |

| Equipment Material | 304 stainless steel material (thickness 1.5㎜) |

| Equipment Pipe Material | PPH material (features are as follows)

Long service life, high temperature resistance, strong acid and alkali resistance, no scaling, easy to replace |

| Applicable Cleaning Fluid | Water-based environmentally friendly cleaning agent |

| Single Cycle Loss | 150-300ml

Depending on the size, quantity, cleaning time, and heating temperature of the cleaning product |

| Input Power | AC380V 50HZ 50A |

| Total Power | 30KW |

| Input Air Pressure | 0.4-0.6MPa |

| Air Flow Volume | 200 L/min @ Cleaning (consumed during cleaning)

600L/Min @ Drying (drying air cut consumption) |

| Exhaust Velocity Requirements | 7.5m³/min, just install Φ125 exhaust pipe |

| Pipeline | Three pumps and three pipelines (features are as follows)

Independent pump and independent pipeline can effectively avoid liquid leakage and reduce the working frequency of the pump to extend the frequency of use |

| Drying Method | 720-degree rotating all-round wind cutting + hot air drying |

| Drying Principle | Heating pipe box heating + blower hot air return +

Cleaning Basket Rotating Top, Side Air Knife Air Cutting |

| Drying Temperature | Room temp-80° |

| Number of Nozzles | 56pcs |

| Number of Cleaning Tanks | 1pc |

| Number of Rinse Tanks | 1pc |

| Closing Method of Cleaning Tank | The first layer: steel door seal

The second layer: It is sealed with an anti-corrosion sealing ring, and the imported safety valve is closed to effectively protect the safety of the operator and the product. |

| Cleaning Ability | Solder slag, rosin, and flux can be thoroughly cleaned |

| Wash + Dry Time | Solvent cleaning: 3-5 minutes (for reference only)

Rinse: 2-3 minutes (for reference only) Drying: 5-8 minutes (for reference only) According to the product requirements, the cleaning, rinsing and drying time can be set freely separately from 1-999S |

| Cleaning Fluid Replacement Method | Equipped with special pipeline for automatic extraction |

| Cleaning Solution Treatment Method | Equipped with special pipeline for automatic extraction |

| Viewport | YES |

| Operation Panel | Touch screen, buttons, emergency stop, start key, reset key |

| If it used in COB jig cleaning | YES |

| Consumables | Filter element, water-based cleaning agent |

| Maintenance items, frequency and time-consuming | 1. Filter element replacement: 1 month (replacement takes 5 minutes)

2. Replacing the solvent: 1 month (replacement takes 30 minutes) 3. Sprinkler head cleaning: 6 months (cleaning takes 10 minutes) The above is for reference only, and can be selectively replaced according to the cleaning frequency of the product. |