Reflow soldering ndiyo njira yomwe imagwiritsidwa ntchito kwambiri polumikizira zida zapamtunda pama board osindikizidwa (PCBs).Cholinga cha ndondomeko ndi kupanga ovomerezeka solder olowa ndi choyamba chisanadze Kutentha zigawo zikuluzikulu / PCB / solder phala ndiyeno kusungunula solder popanda kuwononga ndi kutenthedwa.

Zinthu zazikulu zomwe zimapangitsa kuti pakhale njira yabwino yopangira reflow soldering ndi izi:

- Makina oyenera

- Mbiri yovomerezeka yobwereza

- PCB/gawo footprint Design

- PCB yosindikizidwa mosamala pogwiritsa ntchito stencil yopangidwa bwino

- Kuyika kobwerezabwereza kwa zigawo zokwera pamwamba

- Zabwino PCB, zigawo zikuluzikulu ndi solder phala

Makina Oyenera

Pali mitundu yosiyanasiyana yamakina opangira ma reflow omwe akupezeka kutengera liwiro la mzere wofunikira ndi mapangidwe / zida zamisonkhano ya PCB yoti ikonzedwe.Uvuni wosankhidwa uyenera kukhala wakukula koyenera kuti ugwire ntchito yopangira chotengera ndi malo.

Liwiro la mzere litha kuwerengedwa monga momwe zilili pansipa: -

Liwiro la mzere (ochepera) =Mabodi pamphindi x Kutalika pa bolodi

Load Factor (danga pakati pa matabwa)

Ndikofunika kulingalira kubwereza kwa ndondomekoyi kotero kuti 'Load Factor' nthawi zambiri imatchulidwa ndi wopanga makina, kuwerengera komwe kuli pansipa:

Kuti athe kusankha olondola kukula reflow uvuni ndondomeko liwiro (tafotokozedwa pansipa) ayenera kukhala wamkulu kuposa osachepera mawerengedwe liwiro mzere.

Liwiro la ndondomeko =Uvuni chipinda mkangano kutalika

Processing nthawi

Pansipa pali chitsanzo cha kuwerengera kuti mutsimikizire kukula koyenera kwa uvuni: -

Wophatikiza wa SMT akufuna kupanga ma board a mainchesi 8 pamlingo wa 180 pa ola limodzi.Wopanga phala la solder amalimbikitsa mphindi 4, mbiri ya masitepe atatu.Kodi ndifunika kuunika kwauvuni kwautali wotani kuti ndikonze matabwa?

Mabodi pamphindi = 3 (180/ola)

Utali pa bolodi = mainchesi 8

Load Factor = 0.8 (2-inch space pakati pa board)

Nthawi Yokhala Nthawi = Mphindi 4

Weretsani Liwiro la Mzere:(3 matabwa/mphindi) x (8 mainchesi/ bolodi)

0.8

Liwiro la mzere = 30 mainchesi / mphindi

Chifukwa chake, uvuni wa reflow uyenera kukhala ndi liwiro la mainchesi 30 pamphindi.

Dziwani kutalika kwa chipinda chotenthetsera cha uvuni ndi liwiro la equation:

30 mu/mphindi =Uvuni chipinda mkangano kutalika

4 mphindi

Kutalika kwa uvuni = mainchesi 120 (mamita 10)

Dziwani kuti kutalika konse kwa ng'anjo kudzapitilira mapazi 10 kuphatikiza gawo lozizirira komanso magawo onyamula onyamula.Kuwerengera ndi kwa HEATED LENGTH - OSATI ONSE OVEN ULENGTH.

1. Mtundu wa conveyor - N'zotheka kusankha makina okhala ndi ma mesh conveyor koma nthawi zambiri ma conveyor a m'mphepete amatchulidwa kuti ng'anjoyo igwire ntchito pamzere ndikutha kukonza misonkhano ya mbali ziwiri.Kuphatikiza pa conveyor m'mphepete, chithandizo chapakati-bodi nthawi zambiri chimaphatikizidwa kuti chiyimitse PCB kuti isagwedezeke panthawi yobwezeretsanso - onani pansipa.Pamene pokonza iwiri mbali misonkhano ntchito m'mphepete conveyor dongosolo chisamaliro ayenera kumwedwa kuti asasokoneze zigawo underside.

2. Kutsekedwa kotsekedwa kwa liwiro la mafani a convection - Pali mapepala ena okwera pamwamba monga SOD323 (onani kuyika) omwe ali ndi malo ochepa okhudzana ndi misala omwe amatha kusokonezeka panthawi ya reflow.Kuwongolera liwiro lotsekeka la mafani a msonkhano ndi njira yovomerezeka pamisonkhano yogwiritsa ntchito magawo oterowo.

3. Automatic control of conveyor and center-board-support widths - Makina ena ali ndi kusintha kwa m'lifupi mwamanja koma ngati pali misonkhano yambiri yosiyana yomwe iyenera kukonzedwa ndi ma PCB osiyanasiyana, ndiye kuti njirayi ikulimbikitsidwa kusunga ndondomeko yokhazikika.

Mbiri Yovomerezeka Yobwereranso

- Mtundu wa solder phala

- Zithunzi za PCB

- PCB makulidwe

- Chiwerengero cha zigawo

- Kuchuluka kwa mkuwa mkati mwa PCB

- Chiwerengero cha zigawo pamwamba phiri

- Mtundu wa zigawo pamwamba phiri

Pofuna kupanga reflow mbiri thermocouples olumikizidwa kwa chitsanzo msonkhano (nthawi zambiri ndi mkulu kutentha solder) m'malo angapo kuyeza osiyanasiyana kutentha kudutsa PCB.Ndibwino kuti mukhale ndi thermocouple imodzi yomwe ili pamtunda wopita m'mphepete mwa PCB ndi thermocouple imodzi yomwe ili pamtunda wolowera pakati pa PCB.Moyenera ma thermocouples ochulukirapo akuyenera kugwiritsidwa ntchito kuyeza kuchuluka kwa kutentha kudutsa pa PCB - yotchedwa 'Delta T'.

Mu mawonekedwe a reflow soldering nthawi zambiri pamakhala magawo anayi - Preheat, soak, reflow and cooling.Cholinga chachikulu ndikusamutsa kutentha kokwanira mumsonkhano kuti asungunuke solder ndikupanga zolumikizira popanda kuwononga zida kapena PCB.

Preheat- Mu gawo ili zigawo, PCB ndi solder zonse zimatenthedwa kuti zilowerere mwapadera kapena kutentha kwapang'onopang'ono kusamala kuti zisatenthe mwachangu (nthawi zambiri osapitilira 2ºC/sekondi - onaninso phala la solder).Kuwotcha mwachangu kwambiri kungayambitse zolakwika monga zigawo kuti ziphwanyike ndi phala la solder kuti splatter ipangitse mipira ya solder panthawi yobwereranso.

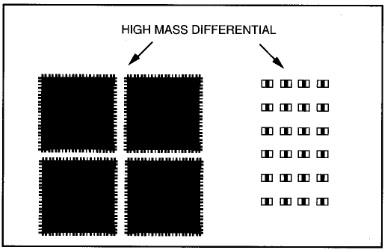

Zilowerere- Cholinga cha gawoli ndikuwonetsetsa kuti zigawo zonse zikufika pa kutentha kofunikira musanalowe mu reflow stage.Kulowetsedwa nthawi zambiri kumakhala pakati pa masekondi 60 ndi 120 kutengera 'kusiyana kwakukulu' kwa msonkhano ndi mitundu ya zigawo zomwe zilipo.Kutentha kotentha kwambiri panthawi yonyowa kumafunika nthawi yochepa.

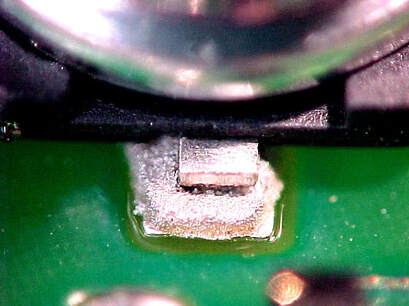

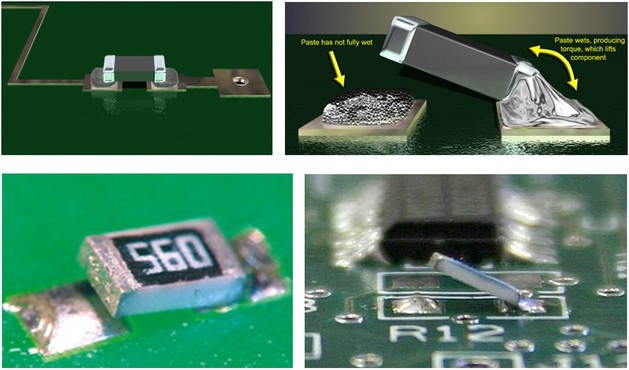

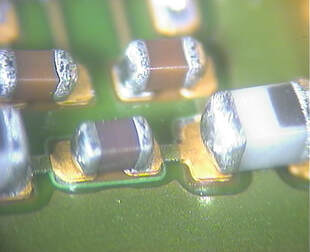

Cholakwika chodziwika bwino cha soldering pambuyo pa kusefukira ndi kupanga mipira yapakati pa chip solder / mikanda monga momwe tawonera pansipa.Njira yothetsera vutoli ndikusintha kapangidwe ka stencil -zambiri zitha kuwoneka apa.

Kuziziritsa- Iyi ndi nthawi yomwe gulu lazizirira koma ndikofunikira kuti musazizire mofulumirirapo - nthawi zambiri kuzizirira kuyenera kusapitirire 3ºC/sekondi.

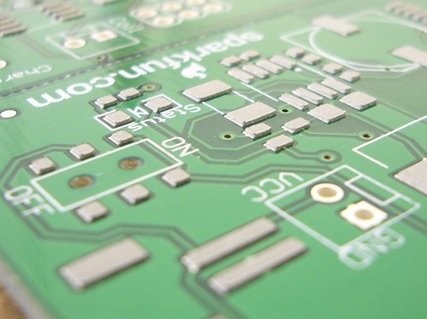

PCB/Component Footprint Design

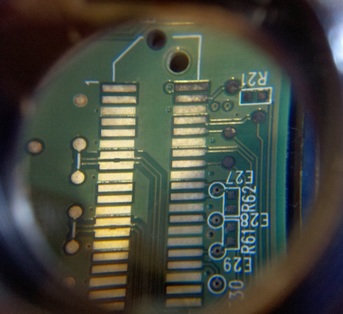

PCB yosindikizidwa mosamala pogwiritsa ntchito stencil yopangidwa bwino

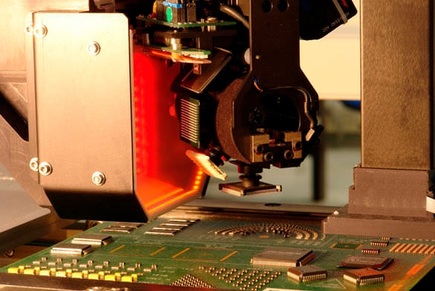

Kuyika kobwerezabwereza kwa zigawo zokwera pamwamba

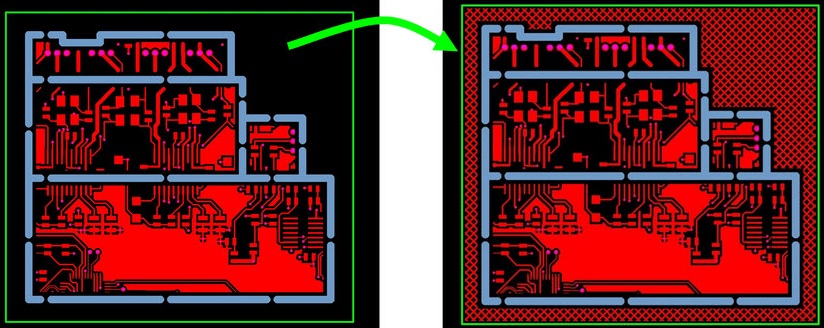

chigawo makhazikitsidwe mapulogalamu akhoza analenga ntchito sankhani ndi malo makina koma ndondomeko si zolondola monga kutenga centroid zambiri mwachindunji PCB Gerber deta.Nthawi zambiri izi centroid deta zimagulitsidwa kunja kuchokera PCB kapangidwe mapulogalamu koma nthawi zina palibe ndipo koterontchito yopanga fayilo ya centroid kuchokera ku data ya Gerber imaperekedwa ndi Surface Mount Process.

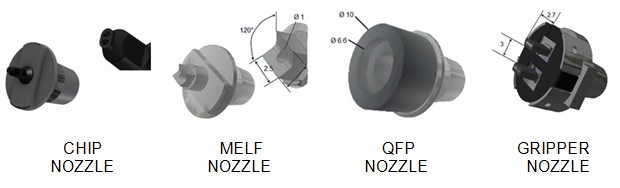

Makina onse oyika zida azikhala ndi 'Placement Accuracy' yotchulidwa monga: -

35um (QFPs) mpaka 60um (tchipisi) @ 3 sigma

Ndikofunikiranso kuti mphuno yolondola isankhidwe kuti ikhale yamtundu wa chigawocho - mitundu ingapo yamitundu yosiyanasiyana yoyikamo imatha kuwonedwa pansipa:

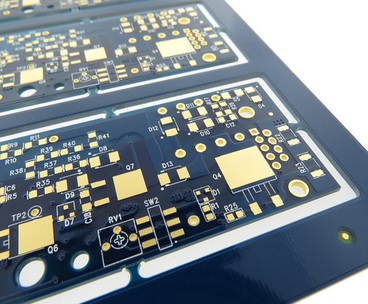

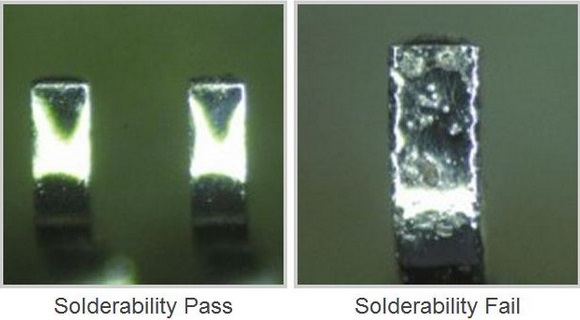

Zabwino PCB, zigawo zikuluzikulu ndi solder phala

Nthawi yotumiza: Jun-14-2022